Compressed Air Distribution Systems: Ensuring Efficient and Reliable Air Flow for Your Operations - S0030

| Product | Compressed Air Distribution Systems: Ensuring Efficient and Reliable Air Flow for Your Operations |

|---|---|

| Brand | |

| Product Price | 0 LKR |

| Datasheet | Not Available |

Description

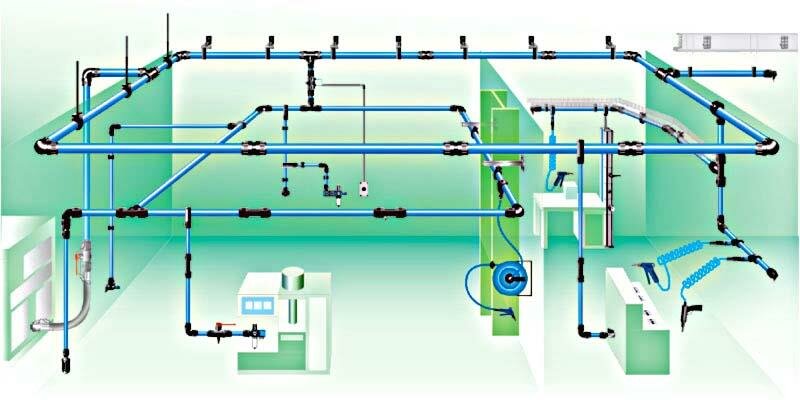

A compressed air distribution system plays a crucial role in ensuring that compressed air is delivered efficiently, reliably, and consistently to the various tools, machinery, and equipment across your facility. Whether you are running a small workshop or managing a large-scale industrial operation, an effective compressed air distribution system is key to minimizing energy costs, reducing downtime, and improving productivity. At FieldInstruments.lk, we provide high-quality, tailored solutions for compressed air distribution systems that meet the unique needs of businesses in Sri Lanka.

What is a Compressed Air Distribution System?

A compressed air distribution system refers to the network of components that transport compressed air from the air compressor to various points of use throughout a facility. The system includes:

- Piping: The network of pipes that carry compressed air from the air compressor to the equipment or machines.

- Valves: Used to control the flow of compressed air and to isolate parts of the system when maintenance or repairs are needed.

- Fittings and connectors: These are used to join various sections of piping and connect the air supply to equipment.

- Filters and regulators: To ensure clean, dry, and regulated air reaches the equipment.

A well-designed compressed air distribution system ensures optimal performance by maintaining consistent pressure, reducing energy consumption, and ensuring minimal leaks.

Why is a Good Compressed Air Distribution System Important?

Having a properly designed and maintained compressed air distribution system is vital for the following reasons:

- Energy Efficiency: A well-designed system minimizes friction loss, reducing energy consumption. The more efficient your distribution system, the lower your operating costs.

- Minimizing Air Leaks: Air leaks can account for a significant portion of energy waste. An efficient distribution system with leak prevention measures ensures maximum airflow with minimal energy loss.

- Maintaining Consistent Pressure: Uniform air pressure across the facility ensures that all machines and tools are operating optimally. Inconsistent pressure can lead to inefficiencies and production delays.

- Safety and Reliability: Proper maintenance and system design enhance the reliability and safety of your operations. It prevents unexpected shutdowns and the risk of system failures.

Key Components of a Compressed Air Distribution System

At FieldInstruments.lk, we offer a range of high-quality components for a complete compressed air distribution system, tailored to your specific needs. These components include:

1. Air Piping

The piping system serves as the backbone of your distribution network. Choosing the right type of piping material is crucial for the system's durability, efficiency, and ease of installation. Common materials include:

- Aluminum Piping: Lightweight, corrosion-resistant, and easy to install. Ideal for a variety of industrial environments, aluminum piping provides a smooth internal surface, minimizing air pressure loss and reducing the chances of air leaks.

- Stainless Steel Piping: Durable and corrosion-resistant, stainless steel piping is perfect for high-pressure and harsh environments, ensuring longevity and safety.

- Plastic Piping: Cost-effective and easy to install, plastic piping is suitable for smaller systems or less demanding environments, offering a smooth surface to reduce friction loss.

2. Air Compressors and Storage Tanks

Compressed air is generated by air compressors and stored in storage tanks for later use. When designing the distribution system, it's essential to ensure that the air compressors and storage tanks are appropriately sized to meet the demands of your operations. Our air compressors offer energy-efficient solutions that ensure high performance and reliability, while our storage tanks provide a constant supply of compressed air.

3. Valves and Regulators

Valves control the flow of air through the system, ensuring that air is delivered to specific areas when needed. Pressure regulators maintain consistent air pressure throughout the system, preventing damage to tools and equipment. We offer a wide variety of:

- Shut-off valves: To isolate sections of the system for maintenance or repairs.

- Flow control valves: To regulate the amount of air flow to specific parts of the system.

- Pressure regulators: To control the air pressure within acceptable limits.

4. Filters and Moisture Removal

To maintain the quality of compressed air, filters and moisture separators are installed throughout the distribution network to remove contaminants like oil, water, and dirt that can damage equipment or affect production quality. We offer:

- Coalescing Filters: These filters remove water and oil from compressed air, preventing rust, corrosion, and product contamination.

- Dryers: Air dryers remove moisture from the air before it reaches sensitive equipment, preventing corrosion and ensuring clean, dry air.

- Particulate Filters: These capture particles and dirt that could damage machinery or disrupt production.

5. Connectors and Fittings

Connectors and fittings allow different parts of the distribution system to be joined together seamlessly. Proper installation of these components ensures an airtight, leak-free system. We offer:

- Quick-connect fittings: For easy connection and disconnection of tools and equipment.

- Tee and elbow fittings: To change the direction of airflow and direct air where needed.

Benefits of Efficient Compressed Air Distribution Systems

- Optimized Energy Use

One of the most significant advantages of a well-designed compressed air distribution system is energy efficiency. By reducing friction losses, preventing leaks, and ensuring uniform pressure, businesses can achieve substantial energy savings. Lower energy consumption translates directly to reduced operational costs. - Increased Productivity

A reliable, well-maintained compressed air system ensures that tools and machinery operate at peak performance. This means fewer breakdowns, fewer delays, and improved overall productivity, which is crucial for meeting production targets. - Reduced Downtime

A system with minimal leaks and reliable components is less prone to unexpected failures. By investing in a high-quality distribution system, you reduce the risk of downtime and keep your operations running smoothly. - Cost Savings

Energy-efficient systems and well-maintained components can significantly reduce maintenance and operational costs. The avoidance of leaks alone can save a substantial amount of money over time, while the optimal performance of your air compressors ensures that they work at their most efficient. - Improved Air Quality

The filters, dryers, and moisture removal systems in a compressed air distribution system ensure that the air remains clean, dry, and safe for use in various industrial processes. Clean air helps protect sensitive equipment, reduces wear and tear, and prevents product contamination.

Industries That Benefit from Compressed Air Distribution Systems

Our compressed air distribution systems are ideal for a wide range of industries in Sri Lanka, including:

- Manufacturing: Power tools, pneumatic machines, assembly lines, and automation equipment.

- Food and Beverage: Clean, dry air for packaging, processing, and handling.

- Pharmaceuticals: Ensure high-quality, oil-free air for drug production and packaging.

- Automotive: Power pneumatic tools, spray guns, and assembly equipment.

- Textiles: Compressed air for weaving, spinning, and finishing processes.

- Agriculture: Control environments in greenhouses, and power air-based machinery.

Why Choose FieldInstruments.lk?

At FieldInstruments.lk, we are committed to providing top-tier compressed air distribution systems that are tailored to your specific needs. Here’s why you should choose us:

- Expert Design and Consultation: Our team of experts will work with you to design a compressed air distribution system that meets the specific requirements of your facility.

- High-Quality Components: We offer durable, energy-efficient piping, filters, regulators, valves, and more, all sourced from trusted brands.

- Energy Efficiency: Our solutions help you reduce energy consumption and lower operating costs, boosting your profitability.

- Comprehensive Support: We provide installation, maintenance, and troubleshooting services to keep your compressed air system running smoothly.

- Custom Solutions: Whether you need a small-scale system or a large, industrial network, we customize every component to your specifications.

Get Started with Your Compressed Air Distribution System Today

If you're ready to optimize the performance and efficiency of your compressed air system, FieldInstruments.lk has the perfect solution for you. Our compressed air distribution systems are designed to deliver reliable, efficient, and cost-effective air flow to your operations.

Contact us today to learn more about how we can help you streamline your compressed air system and improve your productivity and energy efficiency.

Compressed Air Distribution Systems Sri Lanka, Compressed Air Piping, Industrial Air Distribution, Air Compressors and Storage Tanks, Air Filters and Regulators, Energy Efficient Air Distribution, Compressed Air for Manufacturing, Piping for Compressed Air Systems, Compressed Air System Design, Air Distribution Systems for Sri Lanka, Air Compressors for Agriculture, Pneumatic Tools Sri Lanka, Industrial Air Compressors, Compressed Air Maintenance Services, Industrial Air Filters Sri Lanka.

Contacts and Delivery

Fieldinstruments.lk

50/3, Angampitiya Rd, Ethul Kotte, Sri Lanka. 10100.

Phone: +94718555888 Email: info@fieldinstruments.lk